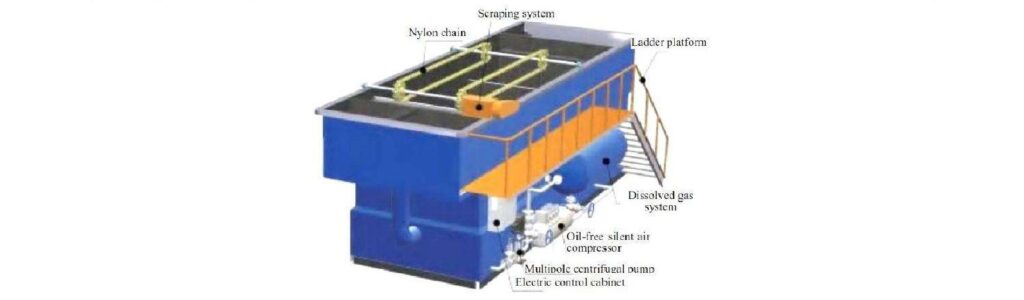

I.Operating Principle of DAF System

Dissolved air flotation (DAF) operates by dissolving air into water under pressure to form saturated water. When released through a pressure release device, it generates micro-bubbles that adhere to coagulated flocs (formed by PAC/PAM addition). This reduces floc density below 1.0, enabling separation from water. The coreAir dissolution system determines separation efficiency; unstable systems cause floc carry-over. An excellent dissolved air system can provide stable suspension effect. When PAC and PAM are added to wastewater, flocculants are formed. These flocculants are then suspended on the water surface through the air flotation equipment. If the dissolved air system is unstable, the flocculants will be mixed in the water, failing to achieve the effect of separating water from suspended solids.

II.Application Objectives & Industries

DAF removes suspended solids to clarify water and reduce COD. It applies to:

Papermaking – Dyeing – Electroplating

Chemical – Food – Oil refining wastewater

III.Municipal Water & Desalination Pretreatment

For municipal tap water purification, high-rate DAF offers simplicity and stability, unaffected by start/stop cycles. Ideal for algae/turbidity removal (rise rate: 25m/h). In seawater desalination treatment, DAF equipment, as a pretreatment process for seawater desalination, has been widely applied in regions such as the Middle East and Asia, and has gained great recognition.

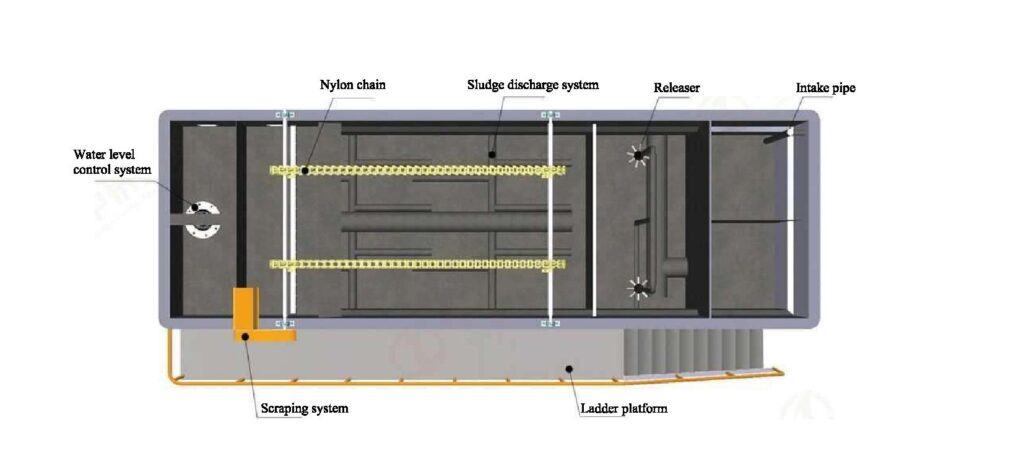

IIII.Robust Sludge Scraper System

The slag scraping system cyclically scrapes the scum floating on the water surface of the tank into the scum pool and discharges it out of the air flotation machine. The motor for slag scraping should not be considered under the condition of saving space; the principle of safety first must be adhered to. If the slag scraping system is damaged, it will prevent suspended solids from being discharged from the air flotation machine, leading to its paralysis and inability to function. A sturdy and durable slag scraping system contributes to the long-term stable operation of the air flotation machine.

IIIII.Widely Applied Scenarios of High-Efficiency Air Flotation Equipment in Wastewater Treatment

- Treating various types of wastewater containing small suspended solids, algae, micro-flocs and other substances whose density is close to or lower than that of water, which are difficult to achieve solid-liquid separation by sedimentation.

- Recovering useful substances from industrial wastewater, such as pulp fibers and fillers in papermaking wastewater.

- Replacing secondary sedimentation to separate and concentrate excess activated sludge, especially suitable for biochemical treatment processes that are prone to sludge bulking.

- Separating and recovering suspended oil and emulsified oil from oil-containing wastewater.