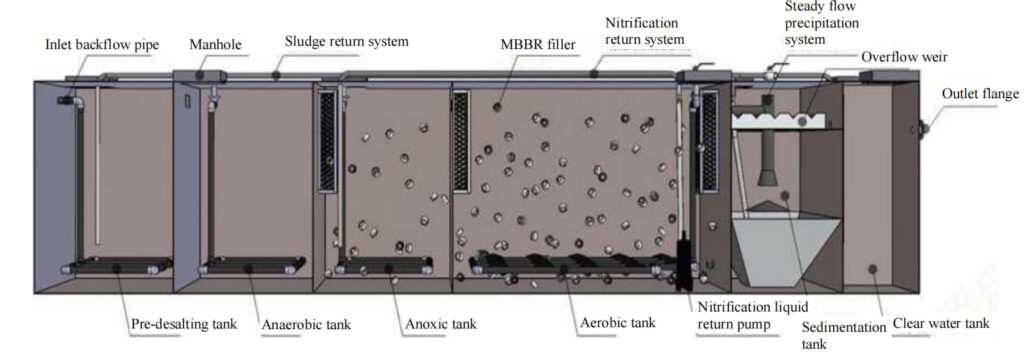

MBBR Integrated Wastewater Treatment Unit

MBBR integrated sewage treatment equipment is an advanced moving bed biofilm reactor (MBBR for short) process, an efficient sewage treatment equipment independently developed by the company through innovation. The principle of the MBBR process is to increase the biomass and biological species in the reactor by adding a certain amount of suspended carriers, thereby improving the treatment efficiency of the reactor. Since the filler density is close to that of water, it is in a state of complete mixing with water during aeration. The environment for microbial growth is three-phase: gas, liquid and solid. The collision and shearing action of the carrier in water makes the bubbles smaller, thus improving the utilization rate of oxygen. In addition, there are different biological species inside and outside each carrier. Anaerobic or facultative bacteria grow inside, and aerobic bacteria grow outside, so that nitrification and denitrification exist simultaneously, thus improving the treatment effect.

The MBBR process relies on aeration in the aeration tank and the lifting of water flow to make the carrier in a fluidized state, and then forms the suspended growth of activated sludge and the attached growth of biofilm. This makes the moving bed biofilm occupy the entire reactor space, and the suspended filler can frequently contact with sewage, so it is called “moving biofilm”.